KNOWLEDGE LIBRARY

INTRODUCTION TO REGENT STREET DISEASE & CATHODIC PROTECTION

Document Type: Briefing

Author: Chris Wozencroft

Revision: 00

Revision Date: 25th November 2018

Regent Street Disease [or Deansgate Disorder] is a structural/material condition affecting early 20th Century Steelframed, masonry-clad buildings.

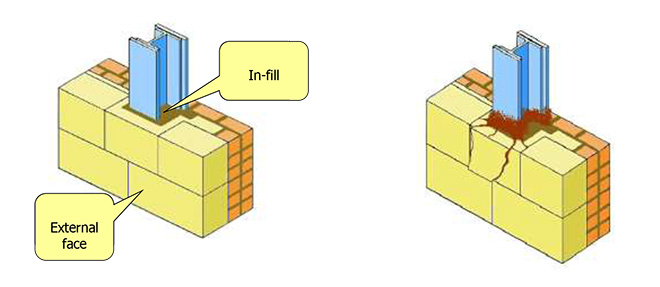

In the late-Victorian, Edwardian and inter-war period, many buildings were constructed with skeletal structural frames of steel and/or iron. These buildings were then clad in masonry with the voids around the frame loosely infilled with grout, rubble and/or concrete. Although there are several advantages to this form of construction [rigidity, fire-protection] the result is that, in certain circumstances, this environment will lead to expansive corrosion of the metal.

When metal corrodes it expands by seven to ten times the volume of the original metal. In this way, relatively low levels of corrosion can create large tensile forces within the masonry, causing cracking and displacement of the cladding, without structurally significant section-loss. The parallel cracking at beam and column locations is often referred to as Regent Street Disease.

Cathodic Protection [CP] is an electrochemical technique used for controlling corrosion of various structures. The technique is most commonly used on marine structures, buried pipelines and sometimes reinforcing steel in concrete.

There are essentially, three basic forms of CP:

- Galvanic – where a more reactive metal is embedded in the surrounding material, and this metal sacrificially corrodes instead of the structure.

- Impressed Current – where an inert metal is embedded in the surrounding material and a DC power supply is used to make the metal behave as though it is corroding instead of the structure.

- Hybrid – A combination of the above, often in two phases [impressed current followed by galvanic].

In the 1990s this technique was adapted for treating Regent Street Disease. Unlike reinforced concrete or pipelines buried in soil, there is an additional challenge for historic buildings, in that the installation of the system has to be aesthetically sympathetic and cause minimal disruption to the heritage materials.

CP components are often installed into the masonry joints on the outside of the building or from the inside face where they can be hidden behind internal finishes. Any solution requires careful consideration of the heritage listing [if any] and coordination with other work/design packages, such as M&E and internal finishes.

In almost all circumstances, only Impressed Current systems can be shown to provide the level of protection required. Masonry is generally drier than soil or concrete requiring high drive-voltages to deliver and distribute the protection current. Galvanic systems [including the galvanic stage of hybrid systems] are usually unable to generate the voltages needed to pass current through the masonry to areas remote from the anode.

The components of CP systems are typically:

- the anodes [small inert metal rods or flat metal strips/ribbon embedded in the masonry]

- the cathode [the steel frame of the building]

- Reference electrodes [small monitoring sensors embedded in the masonry]

- the cabling [insulated copper cables connecting the system, often embedded in masonry joints]

- the control equipment, referred to as the Transformer Rectifier [TR]. A single, or set of, electrical cabinets which provide DC current and collect monitoring data. These are often remotely accessible for monitoring & adjustment.

Although all CP systems require some level of monitoring, Impressed Current systems require regular inspection, testing and adjustment to maintain protection and avoid damage to the system/structure. The monitoring regime is generally, however, straight forward and comparable to many other Planned Preventative Maintenance [PPM] regimes. It will also involve a visual inspection and annual report which are often requirements of heritage and/or insurance requirements.

Although CP is an obscure field within building and civil engineering, it is an established technique with clear qualifications, established performance criteria and many examples successfully completed across a range of structures.

Objective performance criteria and system requirements have been published in the Code of Practice – BS EN ISO 12696:2016 Cathodic Protection of Steel in Concrete. A standard specification for projects has also been published by the Concrete Society as Technical Report 73.

Competence and qualification criteria have also been independently established in the form of BS EN ISO 15257:2017. This document sets out the requirements for competence and certification in CP for the various levels of a project [designer, contractor, monitoring etc] and has been adopted by CSCS and other pre-qualification bodies. In the UK the certification scheme is operated by the Institute of Corrosion.

Assuming that the design and procurement of the package are sensibly managed, CP should not be considered as more complex, challenging or risky than any other specialist sub-contract or design package.

For further information please contact:

Corrosion Engineering Solutions Ltd

64-66 Akeman Street,

Tring, Hertfordshire, HP23 6AF